Silicone Sealant Cartridge Fill Seal Equipment Lotion Filler and Sealer Aluminum Plastic Tube Filling Sealing Machine

Introduction&Function

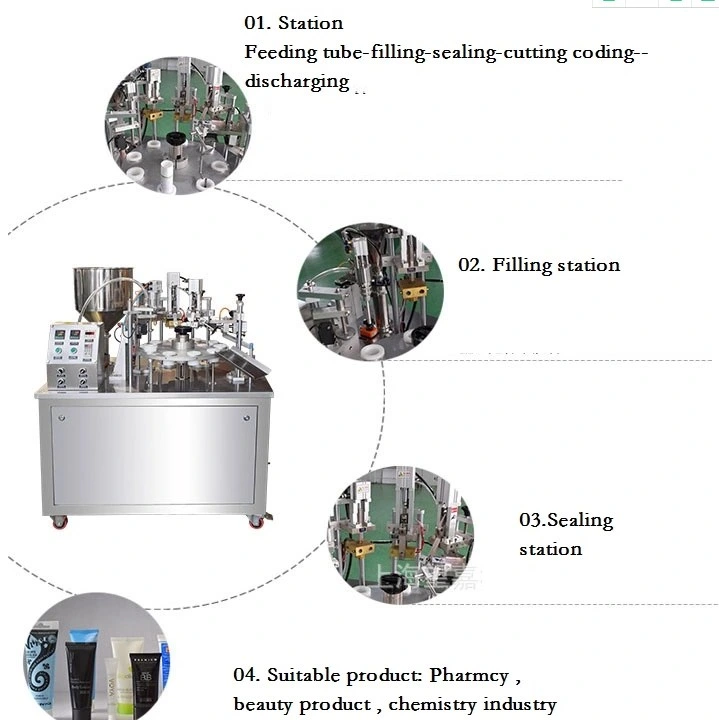

The process of tube filling sealing machine eliminates the use of glue and allows the thermoplastic parts to

bond to itself. Ultrasonic sealing with the proper time setting and pressure is the fastest most reliable method for a variety of tube material sealing.

* Eliminate use of consumable material

* Produce airtight and watertight seams

* Increase production time

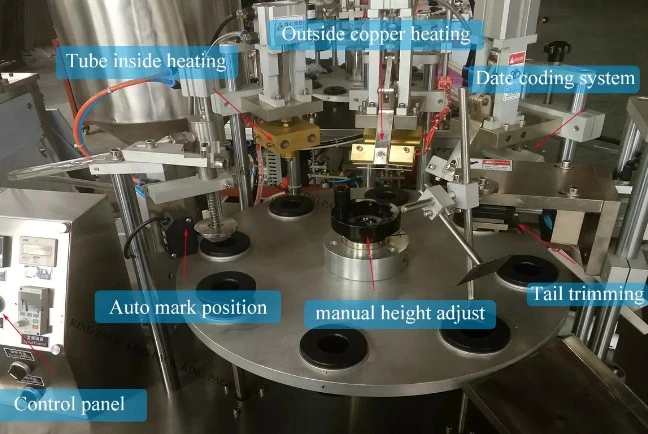

Plastic Tube Filling and Sealing Machine Main Features

1. Auto Tube Feeding; Automatic rotary table with 10 tube holders, servo motor control

2. Adopt digital ultrasonic circuit, stable output and performance

3. Machine body of stainless steel, meet with GMP requirement

4. PLC/HMI control, simple operation and parameters setting

5. Machine with mark searching function, more precise sealing

6. Main parts adopt imported components, Japan and Taiwan

7. Suitable for plastic tubes, composite tubes, PE tubes.

8. Compared with traditional type heat sealing method, the ultrasonic automatic tube filling machine has the following advantages:

* Fast Sealing, save time

* Sealing is nice looking, no plastic melting overflow

* Lower power consumption, energy saving

Characteristics

1. The material contact parts are made of stainless steel SUS304; SUS316 is optional.

2. The connection of the various is used the quick-change device, which is easy to disassemble and clean;

3. high-quality pneumatic components

4. The height of conveyor table can be adjusted easily by a hand wheel for different tubes

5. Pistol plunger filling system processed by digital controlled lathe to guarantee a high filling precision of 1%. And the volume is adjustable.

6. The filling speed can be adjusted freely a VFD

7. Production counter could be displayed on the control cabinet

8. Inner heating and out heating technology, a stable and good looking sealing is got.

Main technical parameters

Power | 220V 50HZ Single phase |

Rate | 1.4KW |

Filling volume | 5--250ml |

Tube diameter | Φ13~40mm,Φ40-50mm |

Producing speed | 20-30pcs/min |

Filling accuracy | ±1% |

Dimension | 1200*850*1500mm |

Weight | 350kg |

Working air pressure |

|