Automatic Cup filling & sealing machine

Features:

Automatic cup filling and sealing machine is mainly used for cups, bowls, boxes, barrels and containers specially shaped filling and sealing, no special requirements on the material, liquid, paste, granules, so you can mix materials.

Suitable for jelly, juice, jam, yogurt, ice cream, salad, pudding, condiments, beverages, chocolate, mineral water and other food filling and sealing.

Parameter:

Packing step:

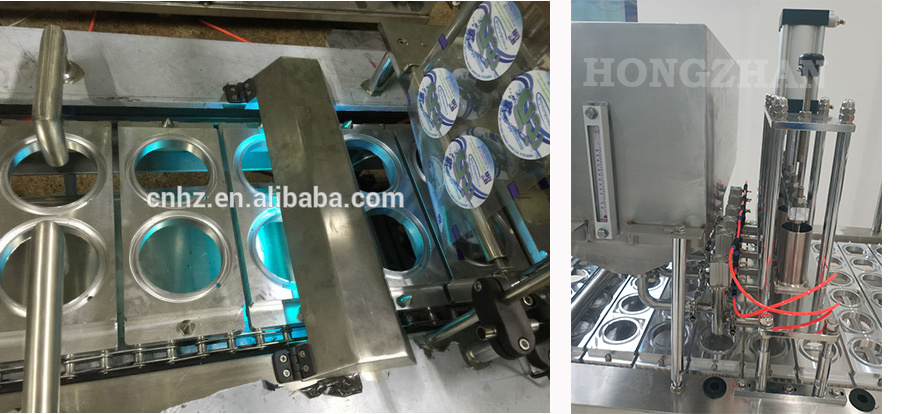

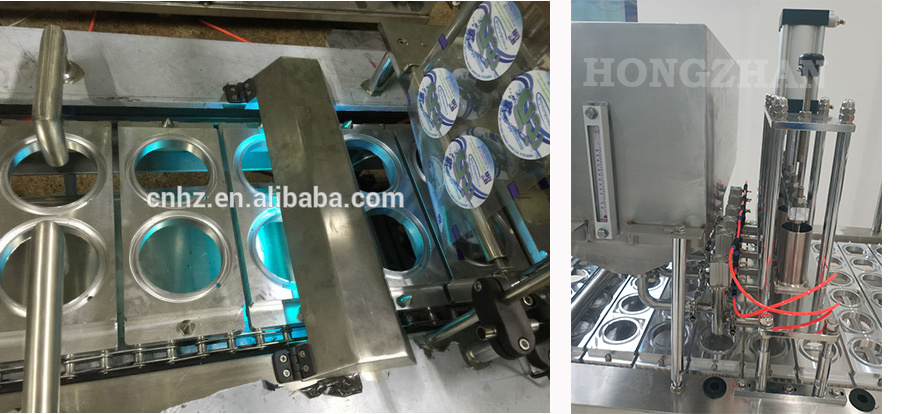

1.Automatic Falling Cup

2.Automatic washing cups (Optional)

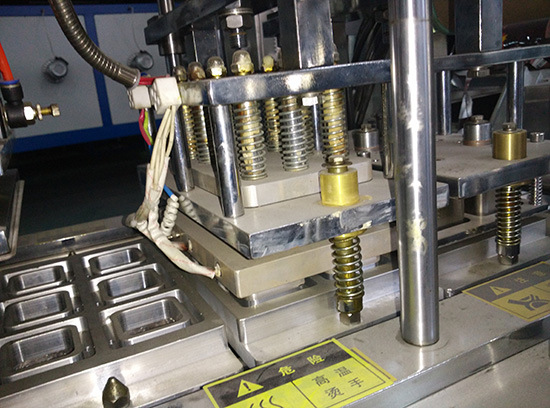

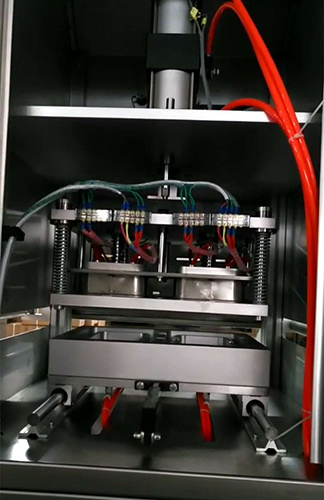

3.Automatic Filling

4.Coding Device

5.UV Germicidal (Optional)

6.Optical Positioning

7.Vacuum and gas filling

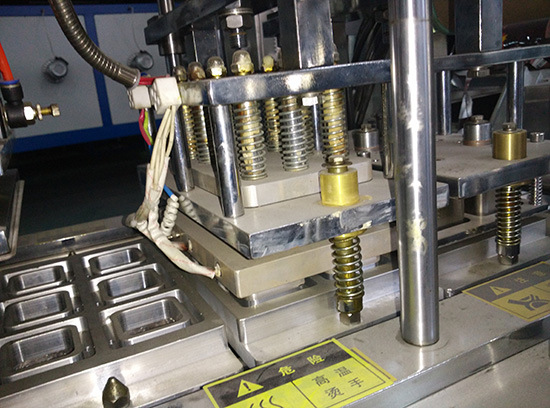

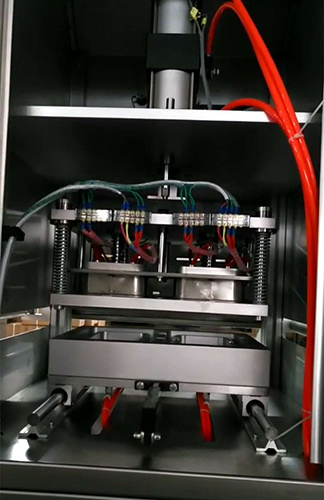

8.Automatic Sealing

9.Waste Film Recycling

10.Vacuum and gas filling for cups

11.Automatic Cup Discharge to conveyor to required place

Features:

Automatic cup filling and sealing machine is mainly used for cups, bowls, boxes, barrels and containers specially shaped filling and sealing, no special requirements on the material, liquid, paste, granules, so you can mix materials.

Suitable for jelly, juice, jam, yogurt, ice cream, salad, pudding, condiments, beverages, chocolate, mineral water and other food filling and sealing.

Parameter:

| Model | BG32A-2C | BG60A-4C | BG60A-8C | BG60A-10C |

| Output (cups/h) | 0-900 or 1800-2000 | 3000-4000 | 7000-8000 | 9000-10000 |

| Filling Range | 20-500ml | 20-500ml | 20-500ml | 20-500ml |

| Voltage | AC 220V / 50Hz | AC 220V / 50Hz | AC 220V / 50Hz | AC 220V / 50Hz |

| Power | 2.5kw | 3.5kw | 6kw | 7.5kw |

| Template | 2 cups 1 time | 4 cups 1 time | 8 cups 1 time | 10 cups 1 time |

| Control System | PLC / MCU | |||

| Capping Film | Roll Film / Sheet Film (Premade Film) | |||

| Metering Methods | Dosing Filling (liquid, paste, granule, powder) | |||

| Air Consumption | 0.6 m3/min | 0.7 m3/min | 0.8 m3/min | 0.9 m3/min |

| Dimensions | 2200*540*1500mm | 3300*710*1700mm | 3900*900*1700mm | 4000*1000*1700mm |

| Weight | 400kg | 700kg | 1000kg | 1200kg |

Packing step:

1.Automatic Falling Cup

2.Automatic washing cups (Optional)

3.Automatic Filling

4.Coding Device

5.UV Germicidal (Optional)

6.Optical Positioning

7.Vacuum and gas filling

8.Automatic Sealing

9.Waste Film Recycling

10.Vacuum and gas filling for cups

11.Automatic Cup Discharge to conveyor to required place