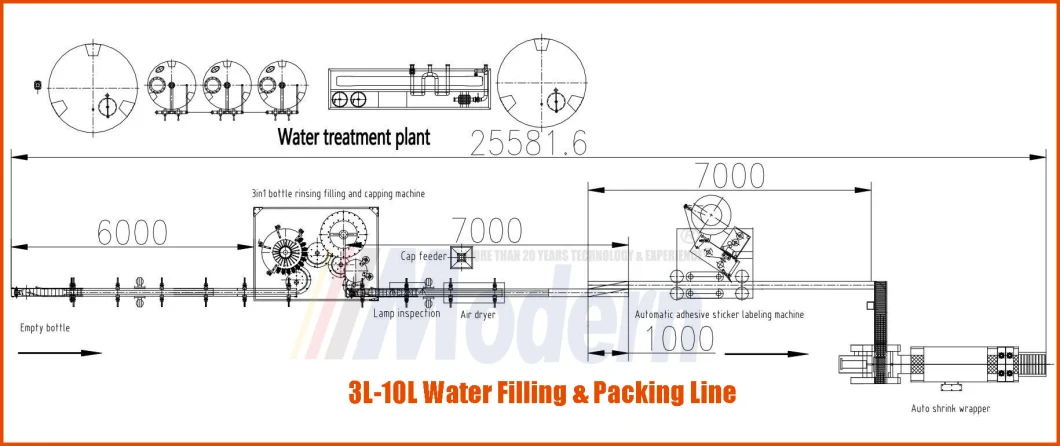

Full Automatic 3L-10L Water Filling line

We supply complete solution of water bottling plant from A to Z, which includs Water treatment system, Automatic bottle rinsing filling capping machine, Air dryer, Automatic labeling machine, Automatic bottle packaging machine, Automatic palletizer system and the whole factory conveyor system.

3L 5L 6L 7L 10L bottle filling line equipment

For the aim of factory's big bottle filling. The 3L-10L PET Bottle Filling Machine Includes the washer, filler and capper are in one machine, smaller and more effective.

For providing a bottle more cleaner and healthier, washing inside and outside by alkalescent liquid, washing inside and outside by disinfectant water, washing inside and outside by pure water and hot sterile water.

This 10L water filling machine works for pure or mineral non carbonated water filling. It works in 3 steps, bottle rinsing, filling, and capping. This series of machine is mainly used for 3L-10L bottle filling the Non-Aerated drink such as mineral water, pure water, non-gas wine drink and so on. The machine design is shorten the time for the drink material contact with outside, Increased the sanitation condition and throughout and economy benefit.

It is very convenient to change bottle size by means of advanced bottle conveying technology--bottleneck clamping & bottle suspending technology.

The Main Machines In The Bottled Water Production Line

Water treatment system( Water purification system) → Bottle blowing machine → Bottle unscrambler →

Bottle filling machine → Bottle labeling machine → Bottle packaging machine

The Cerificate We got

Service

MODERN MACHINERY offers engineer to assist you in installing your bottling machine. Upon installation of your equipment or line, the engineer stays on-site to watch your new equipment run smoothly and train your operators. Even after our specialist leaves your plant, we are ready to give you timely, courteous service when you need it.

Our engineer offers the following services:

1. Installation of equipment or packaging line at the customer's plant

2. Coordinate schedule with mechanics to perform changeovers and preventive maintenance activities

3. Perform mechanical adjustments (if needed) on equipment and packaging line to optimize equipment's performance

4. Resolve equipment issues

5. Provide on-site training on all assigned procedures

An MODERN MACHINERY engineer will be in-charge of the equipment setup and adjustment in your plant. All of the activities will be focused on optimizing the equipment to maximize production output.

About Us

Zhangjiagang Modern Machinery Co., Ltd. is a professional beverage machinery manufacturer, specializing in water filling machine, carbonated soft drink filling machine(CSD machine) and juice production line, as well as various water treatment plant, sterilizing system, hot filling process. As one of the earliest companies engaged in beverage machinery in China.Our products not only sell well in domestic market, but also are exported to overseas countries including Russia, USA, Czech, Albania, Vietnam, Pakistan, Nigeria, Kenya, Senegal, South Africa and more than 20 different countries.

We would like to cooperate with clients to develop long-term steady business relationships.

Looking forward to hearing from you in the near future. Welcome new and old customers to contact us!

At present, we can provide the following complete sets of production lines:

1. 2,000-25,000b/h mineral water & pure water & drinking water production line

2. 2,000-24,000b/h fruit tea & fruit juice hot filling production line

3. 2,000-20,000b/h carbonated soft drink filling line

4. 100-1200b/h 5&3 gallon water filling line

5. 1000-15000b/h wine & beer bottling line

6. 2000-20000 can filling line

Container loading

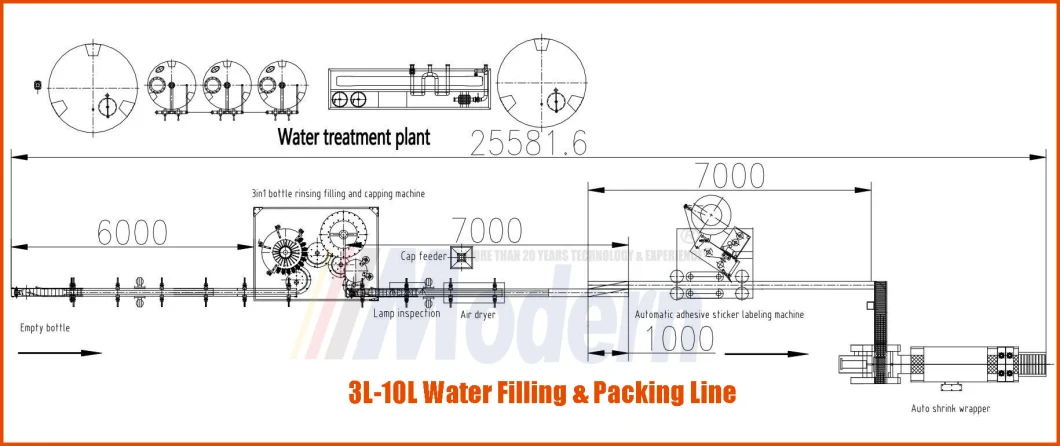

We supply complete solution of water bottling plant from A to Z, which includs Water treatment system, Automatic bottle rinsing filling capping machine, Air dryer, Automatic labeling machine, Automatic bottle packaging machine, Automatic palletizer system and the whole factory conveyor system.

3L 5L 6L 7L 10L bottle filling line equipment

For the aim of factory's big bottle filling. The 3L-10L PET Bottle Filling Machine Includes the washer, filler and capper are in one machine, smaller and more effective.

For providing a bottle more cleaner and healthier, washing inside and outside by alkalescent liquid, washing inside and outside by disinfectant water, washing inside and outside by pure water and hot sterile water.

This 10L water filling machine works for pure or mineral non carbonated water filling. It works in 3 steps, bottle rinsing, filling, and capping. This series of machine is mainly used for 3L-10L bottle filling the Non-Aerated drink such as mineral water, pure water, non-gas wine drink and so on. The machine design is shorten the time for the drink material contact with outside, Increased the sanitation condition and throughout and economy benefit.

It is very convenient to change bottle size by means of advanced bottle conveying technology--bottleneck clamping & bottle suspending technology.

| Model | XGF12-12-4 | CGF18-18-6 |

| Capacity | 1000BPH | 2000BPH |

| Applicable bottle | Plastic bottle 5L-10L Plastic screw cap | |

| Applicable filling content | Mineral water, wine, non-carbonated water | |

| Washing station | 12 | 18 |

| Filling nozzle | 12 | 18 |

| Capping head | 4 | 6 |

| Main motor power | 3.5kw | 5.5kw |

| Water pump power | 0.37kw | |

| Dimension (mm) | 2500*2100*2450 | 3200*2500*2450 |

| Weight (kg) | 4000 | 5000 |

Bottle Rinsing Part:

The rotary wheel is a fully SUS304 stainless steel welded structure.

The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

The rinser is driven by driving system positioned inside machine frame via gear transmission.

The rotary wheel is a fully SUS304 stainless steel welded structure.

The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

The rinser is driven by driving system positioned inside machine frame via gear transmission.

Bottle Filling part:

Rotary wheel fully made of stainless steel SUS 304.

Gravity filling method.

Filling valves are made of SUS304.

Filling valves are reasonably structured with accurate filling.

Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Filler is driven through gears inside the machine frame.

Link-wheels in rinser, filler and capper are transported in ringed support of bottle-neck

Rotary wheel fully made of stainless steel SUS 304.

Gravity filling method.

Filling valves are made of SUS304.

Filling valves are reasonably structured with accurate filling.

Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Filler is driven through gears inside the machine frame.

Link-wheels in rinser, filler and capper are transported in ringed support of bottle-neck

Bottle Capping part:

Sealing faucet (main part to control the credibility of sealing), is improved by experts with the design of alnico.

Besides the magnetic contortion variation device, there is variation dial which makes variation more easily. The benefit of this design is not only water bottling machine can set the contortion, but also it makes contortion more precise and credible, and reduces inferior. Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism. Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch. Centrifugal way of cap arranging is adopted to reduce damage of caps.

A cap inspecting system is applied to control on-off of elevator.

Sealing faucet (main part to control the credibility of sealing), is improved by experts with the design of alnico.

Besides the magnetic contortion variation device, there is variation dial which makes variation more easily. The benefit of this design is not only water bottling machine can set the contortion, but also it makes contortion more precise and credible, and reduces inferior. Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism. Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. The capper is equipped with inlet bottle detection switch. Centrifugal way of cap arranging is adopted to reduce damage of caps.

A cap inspecting system is applied to control on-off of elevator.

The Main Machines In The Bottled Water Production Line

Water treatment system( Water purification system) → Bottle blowing machine → Bottle unscrambler →

Bottle filling machine → Bottle labeling machine → Bottle packaging machine

The Cerificate We got

Service

MODERN MACHINERY offers engineer to assist you in installing your bottling machine. Upon installation of your equipment or line, the engineer stays on-site to watch your new equipment run smoothly and train your operators. Even after our specialist leaves your plant, we are ready to give you timely, courteous service when you need it.

Our engineer offers the following services:

1. Installation of equipment or packaging line at the customer's plant

2. Coordinate schedule with mechanics to perform changeovers and preventive maintenance activities

3. Perform mechanical adjustments (if needed) on equipment and packaging line to optimize equipment's performance

4. Resolve equipment issues

5. Provide on-site training on all assigned procedures

An MODERN MACHINERY engineer will be in-charge of the equipment setup and adjustment in your plant. All of the activities will be focused on optimizing the equipment to maximize production output.

About Us

Zhangjiagang Modern Machinery Co., Ltd. is a professional beverage machinery manufacturer, specializing in water filling machine, carbonated soft drink filling machine(CSD machine) and juice production line, as well as various water treatment plant, sterilizing system, hot filling process. As one of the earliest companies engaged in beverage machinery in China.Our products not only sell well in domestic market, but also are exported to overseas countries including Russia, USA, Czech, Albania, Vietnam, Pakistan, Nigeria, Kenya, Senegal, South Africa and more than 20 different countries.

We would like to cooperate with clients to develop long-term steady business relationships.

Looking forward to hearing from you in the near future. Welcome new and old customers to contact us!

At present, we can provide the following complete sets of production lines:

1. 2,000-25,000b/h mineral water & pure water & drinking water production line

2. 2,000-24,000b/h fruit tea & fruit juice hot filling production line

3. 2,000-20,000b/h carbonated soft drink filling line

4. 100-1200b/h 5&3 gallon water filling line

5. 1000-15000b/h wine & beer bottling line

6. 2000-20000 can filling line

Container loading